ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

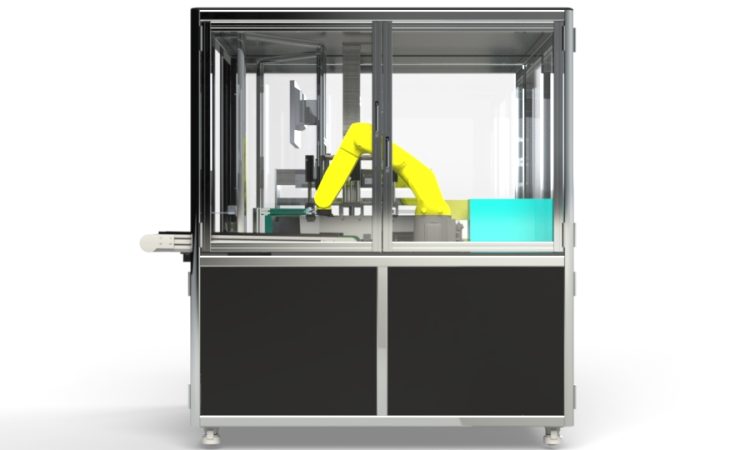

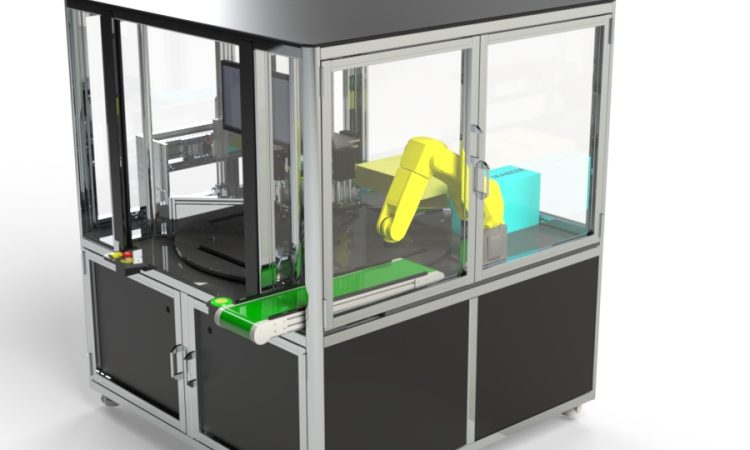

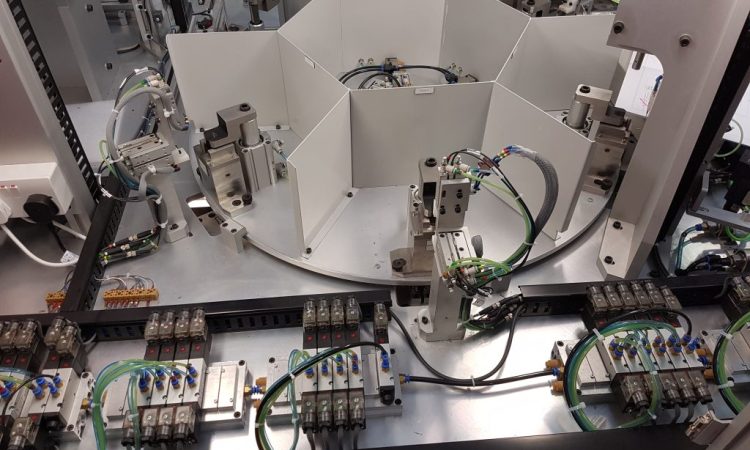

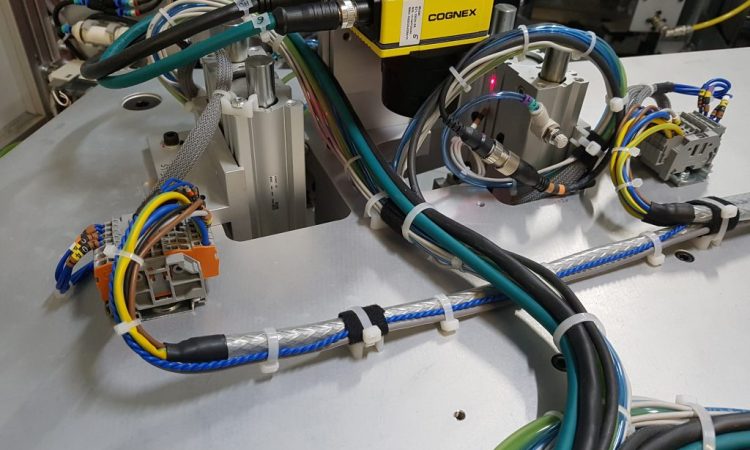

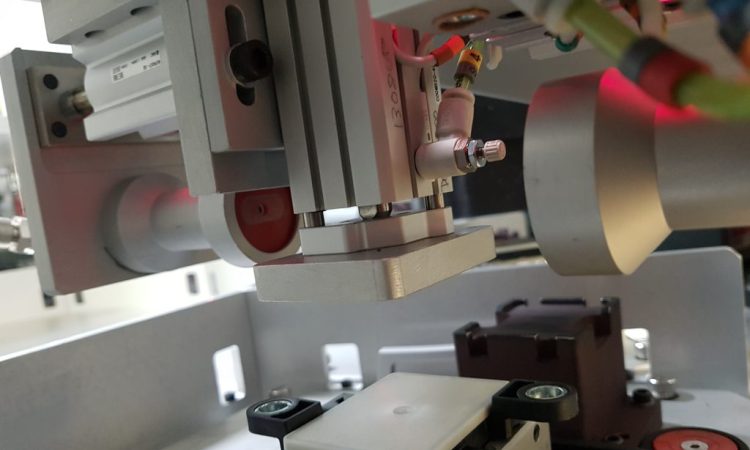

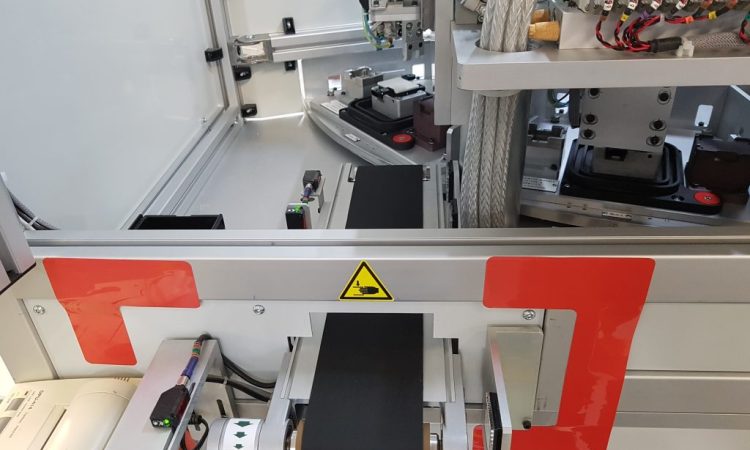

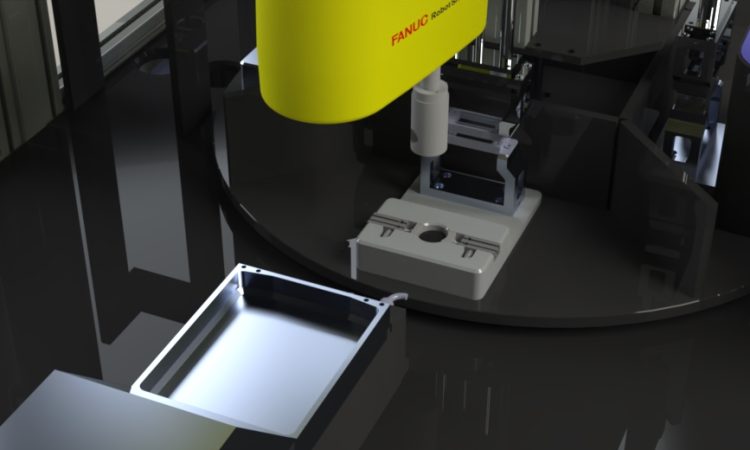

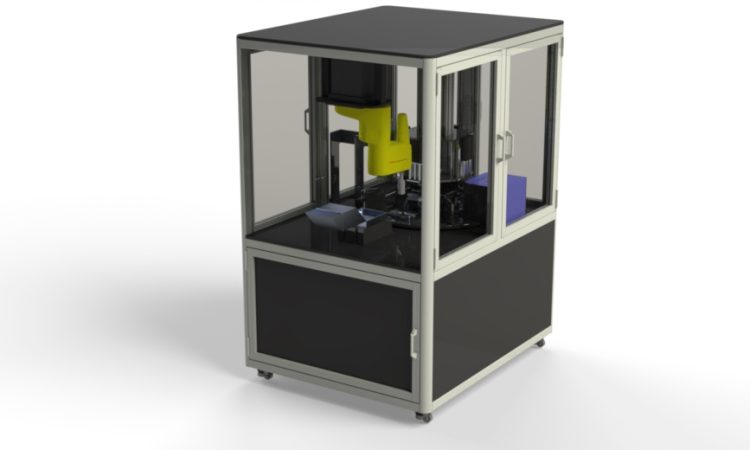

Rotary Assembly Machines

Rotary Assembly Machines

For more complex production processes, rotary assembly machines and rotary indexing machines provide an extremely cost-effective and efficient solution. Allowing for the number of operators to be significantly reduced, whilst still allowing for multiple parallel processing and parallel production to be carried out, can offer significant benefits to our clients.

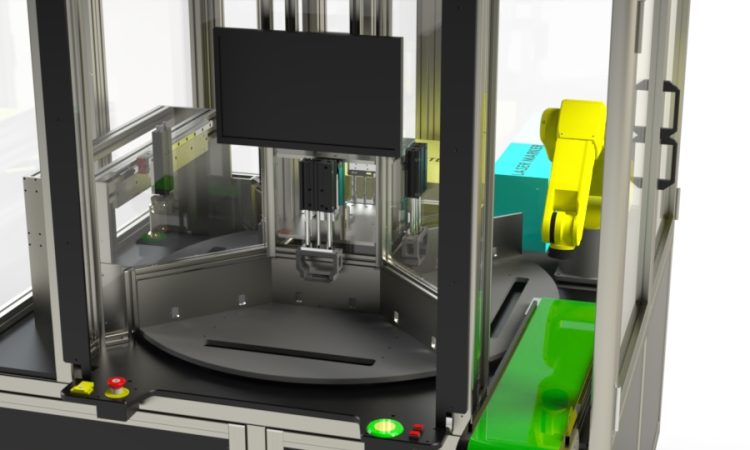

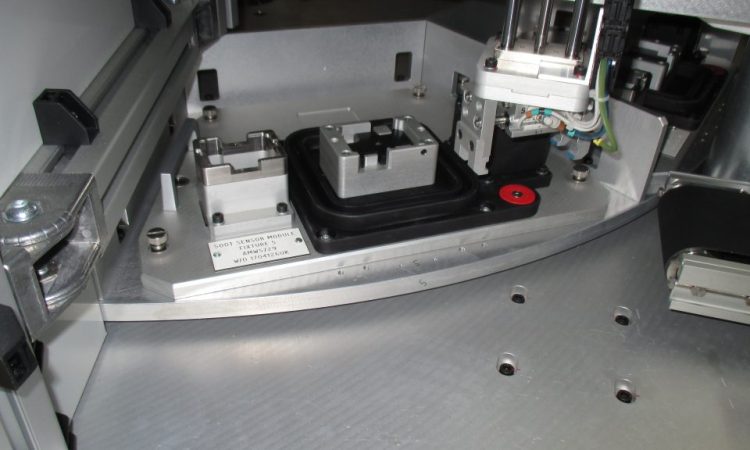

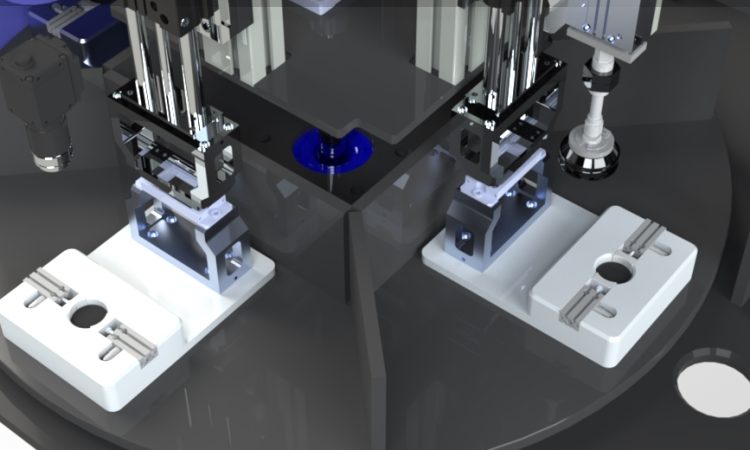

Rotary Machine Applications

Leak testing, flow testing, vision inspection, insertion and insertion force testing, bowl feeding, adhesive & sealant application, laser marking, communications, and electrical compliance testing are just a few of the processes that have been successfully integrated to meet our clients’ exacting requirements, demonstrating the incredible flexibility of rotary assembly and test machines.

Benefits include:

Reduction in human error

Quicker cycle times

Reduced product handling

End-to-end product traceability

Significant cost benefits in terms of reduced labour, scrap, hardware and floorspace

Plastic mouldings

Heat engines

Valves & solenoids

Manifold assemblies

EV battery modules