ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

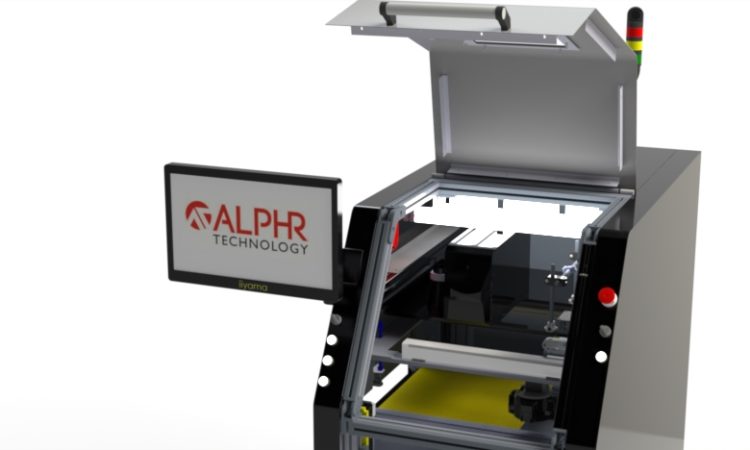

In-Line-Laser Marking Solutions

In-Line Laser Marker Solutions

In-Line Laser Marking Solutions

The code to be marked on the product is programmable by the client. The marking types available for the user to programme can be one or any combination of Font, 1D Barcode, 2D Code, Gs1 DataBar, and Logo image.

During a single pass, the PCB is clamped and transported on an adjustable width conveyor under a fixed laser marking head.

The standard marking area is up to 330 by 330 mm with one stop. With a second stop position, the marking area can increase to 330 by 450 mm. Both marking area options are a standard feature of the machine.

After marking, the code is scanned and gauged to check the correct information has been marked and is legible, prior to the product being moved out the laser marking area and unclamped from the conveyor.

ALPHR can offer Hybrid (fibre & YV04; wavelength 1064nm) and UV (wavelength 355nm) laser technology as standard. Other laser marking technologies such as green, fibre, and C0 2 are also available as required.

Fully ESD compliant

Adjustable width conveyor

Smema extended option

Automatic readability/quality check

Fully traceable communication