Menu

Menu

Menu

ALPHR UK

Amor Way, Dunhams Lane,

Letchworth, Hertfordshire, SG6 1UG

Letchworth, Hertfordshire, SG6 1UG

Home » Modular Automation Solutions » Flexi Pod Automation

Need more information, or thinking about working with us?

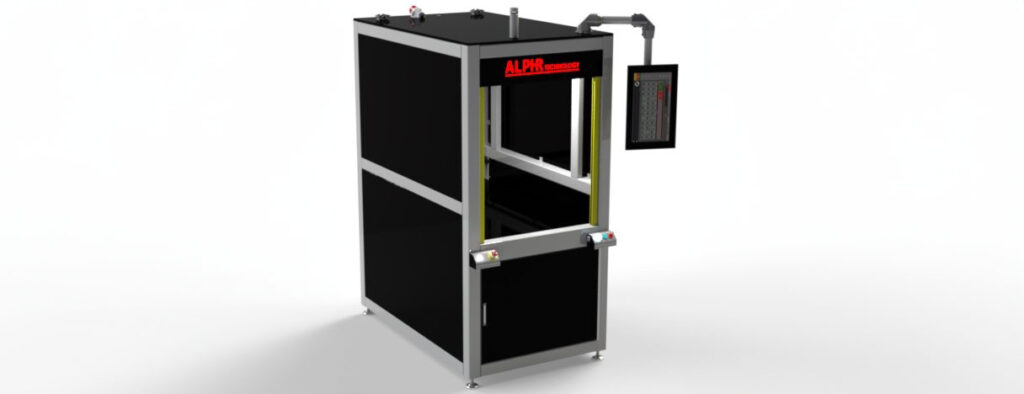

Flexi Pod Automation

Flexi Pod Automation

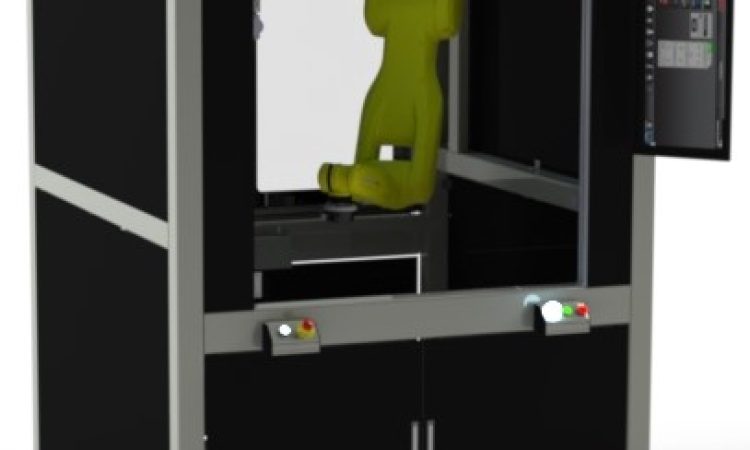

Designed to support modern production processes requiring robots, palletised assembly or rotary indexing tables, the Flexi-Pod utilises standard frames, and controls architecture to create a flexible, modular platform.

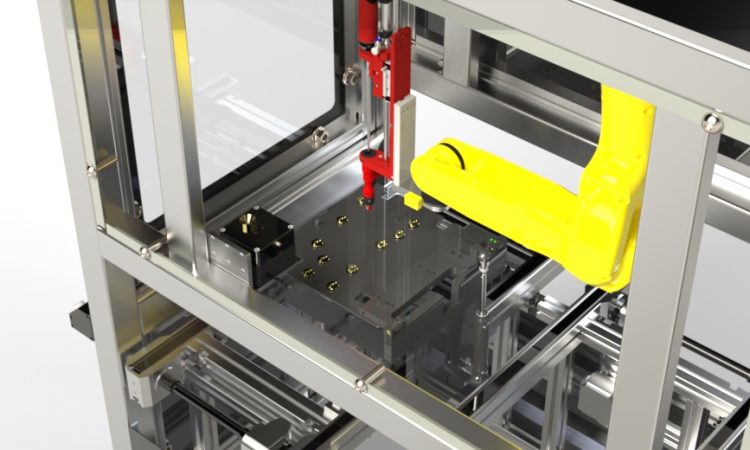

The Flexi-Pod can be supplied in a single or multi-station configuration, enabling a wide range of processes to be accommodated on a single platform, including automatic screwdriving, dispensing, laser marking, vision inspection, End-of-Line testing, pick & place, leak/flow testing, and assembly.

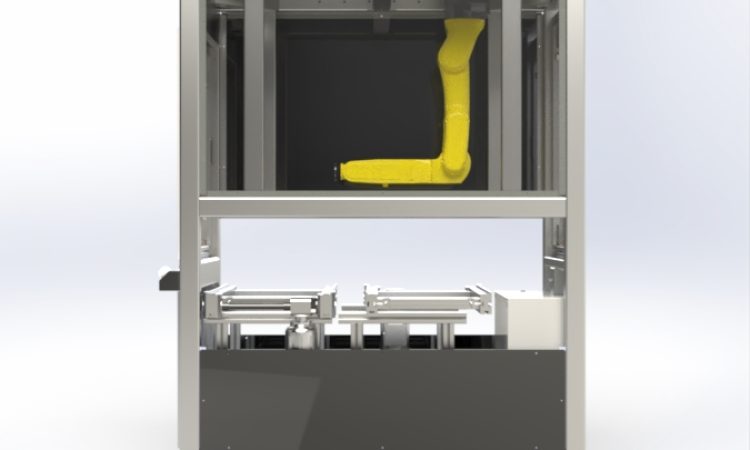

With a welded structure, the Flexi-Pod is designed to support up to two robots working simultaneously or up to a four-station rotary table.

The flexible, modular design allows additional stations to be easily added as production demands increase. Changes to tooling can be quickly implemented to accommodate new variants or changes to existing products.

Our Production Flexi-Pod Range

Shorter lead times, ease of maintenance, improved serviceability, reduced spares, quicker factory implementation, and a more cost-effective solution resulting in a quicker ROI are just some the benefits available with the Flexi-Pod.

Standard Flexi-Pods:

1000mm (W) x 1600mm (D)

1200mm (W) x 1600mm (D)

1600mm (W) x 1600mm (D)

Options include:

Monitor arm

SCADA HMI

Light guard or safety door

Centralised PLC control system for multiple stations, or individual PLC control system

Infeed/outfeed conveyor, 2 or 4 station rotary or operator workstation

No robot, one robot or twin robot