ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

Vision Inspection – All In One

Vision Inspection – All In One

Vision Inspection – All In One

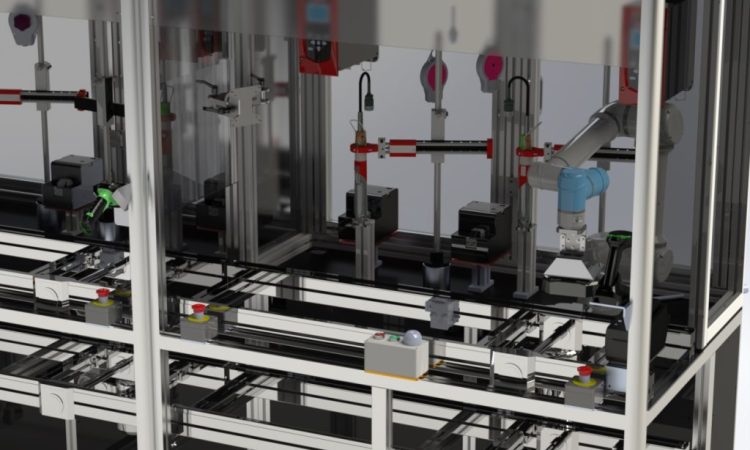

Keyence Intuitive Vision System enables ALPHR Technology to deliver reliable, customised automation testing solutions ALPHR Technology has over 30 years of global experience in providing an industry- leading range of automation solutions for product assembly, including complex assembly machines and portable test equipment. The company, which specialises in end-of-line testing, robotics, Industry 4.0 and test & measurement, has unrivalled expertise in the capture of big data.

Customers around the world have turned to ALPHR for a range of modular and bespoke solutions, whether a relatively straightforward assembly station or a fully automated assembly and test line. The company is driven by the requirements of its customers to provide the best solutions possible, and this was the case when seeking a vision system for use on various automation lines.

ALPHR chose the CV-X Series Intuitive Vision System manufactured by KEYENCE.

Consisting of a controller, camera and lighting solution, this vision system makes use of a wide range of high-resolution cameras designed to satisfy any application need.

It delivers up to 64 megapixels and featuring a multi-spectrum image capture system that uses eight wavelengths of coloured light.

The CV-X Series is not only a powerful and sophisticated vision tool but is also easy-to-use. The vision system also uses the ShapeTrax3 search tool, which enables stable scanning of the target even if changes occur such as chips, contrast reduction and size changes.

Furthermore, it is compatible for communicating with vision guided robots from many manufacturers. This is vital because calibration is the most difficult factor when developing and operating a system that links robots and vision systems so the KEYENCE solution uses an auto-calibration function to provide highly accurate and effortless calibration. Through a single click, reliable and stable results are delivered without the subjectivity of a manual process. Because calibration can be carried out immediately, it’s possible to recover quickly from any positional shift and achieve fast and accurate reproducibility regardless of location.

A key feature of the KEYENCE CV-X Series Intuitive Vision System chosen by ALPHR is the CA-DQP12X Pattern Projection Lighting (PPL) system which offers simultaneous 2D and 3D inspection. Because PPL eliminates blind spots by using eight-directional light transmission to deliver pattern projection, inspection can be carried out without being affected by surface conditions or contrast. By adding height data to conventional 2D inspection, PPL provides dramatically improved stability during inline inspection.

The CA-DQP12X projects multiple stripe patterns at the target surface at high speed and an ultra-fast CMOS sensor and processor analyse the reflected light in real-time to generate a 3D height image.

Says Iqbal Kazi, General Manager at ALPHR: “When implementing a vision system, having the correct lighting is paramount in determining if the installation will be a success or otherwise. KEYENCE was able to demonstrate why a specific light source should be used and proved that the CA-DQP12X PPL system was the right lighting for the applications we operate in.”

For more conventional imaging applications, the CV-X Series makes use of such 2D inspection lighting solutions as LumiTrax capture mode, auto-teach inspection and measurements and dimensions tools, providing stable inspection regardless of surface conditions or variations between parts.

The auto-teach inspection tool uses the image sensor to learn variations and individual differences that exist in non-defective workpieces and recognises

those that differ from the norm. In most cases, dimension or geometric measurement for image processing requires multiple tools and complicated calculation processing but with the CV-X Series measurements and dimensions tools these processes can be carried out through a few simple clicks.

“Not only are KEYENCE’s sales engineers highly knowledgeable of their products but they are also very approachable and willing to help” continued Iqbal Kazi.

“KEYENCE makes the whole process from specifying to integration and set-up as simple as it could be. When working with them we know we are dealing directly with a manufacturer of highly complex hardware, and we can discuss projects with acknowledged experts in their field. KEYENCE can also carry out trials on the product to be tested and create detailed reports, eliminating guesswork.”

This, and the company’s CV-X Series Intuitive Vision System unparalleled capabilities, set KEYENCE apart from the competition.