ALPHR UK

Letchworth, Hertfordshire, SG6 1UG

Need more information, or thinking about working with us?

Vision Inspection Technology

Automated Vision Inspection

The correct implementation of Vision Inspection technology offers many advantages in today’s manufacturing environment. Quality inspection, measurement, part present checking and display testing are just some of the features that manufactures can implement to ensure the reliability and quality of their products.

ALPHR Technology has designed and deployed inspection systems to provide simple checks for part present vision checking, through to more complex visual inspection of LCDs and TFT’s. By partnering with leading OEMs, we integrate technology that is most appropriate for our clients’ requirements but more importantly, we consider all aspects of the process including lighting, environmental conditions, cycle time and operator feedback.

We understand manufacturing, and so we know how vital it is to catch any errors as early as possible in the manufacturing process. Our vision solutions for assembly and test ensure errors are captured early, minimising lost production time and potential material wastage.

Data plays an important role in delivering value through vision-checking systems.

Our information management methodology ensures data is delivered to our clients in a manner which adds valuable to their business.

How Can Vision Inspection Benefit your Business ?

Display testing

LCD, TFT, LED/OLED displays are the critical user interface to many products and ensuring that the end-user experience is perfect is extremely important.

Depending on the display, a wide variety of tests can be carried out but colour, brightness, contrast, pixel quality/density and luminosity, alignment, white balance and viewing angle are some of the most common.

ALPHR experience in display testing ensures the right solution is offered based on the clients’ requirements. Whether checking an LCD display on a boiler is displaying correctly in the right operational sequence or an in-car instrument cluster is showing the right information, at the right time and the touch screen haptics are functioning correctly, we have the experience to advise our clients on the right vision solution for the application.

The integration of this technology is where ALPHR can provide significant benefits to a business. We have supplied solutions worldwide, including standalone machines and fully integrated palletised assembly and test lines. We are proud of our reputation as class-leading experts which has built on reliability, repeatability and quality.

Part-Presence Checking

Part presence inspection confirms the quantity of or the presence/absence of parts or components within an assembly as a whole or the area within the sensor/cameras field of view.

Presence inspection systems are used within automated machines and production lines for purposes of quality control.

There are many potential solutions that can be deployed to meet a client’s part presence checking requirements. For this reason, ALPHR works with industry leading manufacturers of vision systems and sensors to ensure the most appropriate hardware is integrated into the automated solution supplied.

Vision Measurement Systems

Vision measurement systems can be utilised for non-contact measurement across a wide variety of products and industries.

Whereas a traditional contact CMM precisely measures a distance between coordinates, a vision measurement system uses optical elements, sensors, and software to perform its precision measurements and can output both 2D and 3D measurements without the need for physical contact.

This can be an ideal way of rapidly determining if a component, sub-assembly, or assembly is acceptable, speeding up cycle times and improving efficiency.

To ensure we comply with a client’s exacting requirement for vision measurement, trials are conducted with our suppliers to establish the hardware to be proposed and ultimately Integrated into the final solution to ensure it is fit for purpose and meets the project specification.

OCR (Optical Character Recognition)

Machine vision OCR is used to automatically read printed, scribed, or stamped text at high speed to confirm text readability, quality and form.

ALPHR has many years’ experience in integrating vision solutions to carry out OCR checks on printed labels and laser markings to ensure the characters printed or laser marked are legible, contain the correct information, are in the correct position, are printed or marked in the right font type, and are the correct font size.

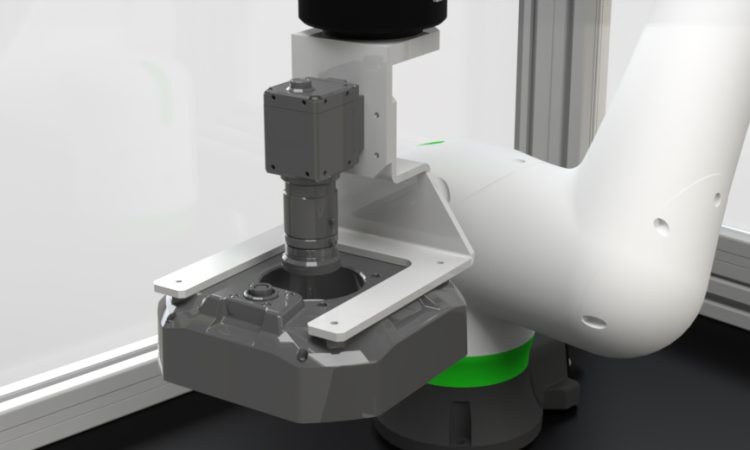

Robot Coordinate Correction

Vision based coordinate correction offers considerable benefits when it comes to the introduction of robotics into modern manufacturing facilities. Used in industry for numerous applications from machine loading, pick and place, screwdriving, soldering, adhesive dispensing, a robot vision solution can dramatically improve efficiency, quality and safety.

Robots and vision systems are readily available for the end user to purchase, but the decision of “what” to use can be more complex. The selection of the correct robot, whether 2D or 3D solutions are appropriate, safety considerations and gripper selection can appear daunting, but this is where ALPHR works closely with our clients to mitigate the fears and risks associated with this technology, guaranteeing the right solution is selected, achieving requirements goals and simplifying the adoption of robotics.

Pick & Place Solutions

Loading a machine, fitting a component, or transferring sub-assemblies was traditionally a manual, monotonous, and low-value task. By incorporating automated pick and place solutions in our designs, ALPHR can help our clients free up valuable labour resources for more value-added processes across the business.

Removing the need for operator loading or potentially costly precision alignment fixtures dedicated to one specific component/part can offer significant savings in cycle time, overheads and efficiency can be realised.

With the continued development of Flexible part feeders, Robotics and 2D/3D vision systems, a wide variety of components to be presented to the pick and place system, either randomly or controlled.

By working closely with our clients and suppliers, ALPHR Technology are able to offer advice and solutions on vision inspection systems that specifically target improved efficiency and quality, a reduction in failures and provide long-term business savings. To find out more, contact our expert team today.